Products

CF Extruder Parts

CF Extrusion enhances our own expertise in component manufacturing by partnering with other manufactures to provide a single source for turn-key solutions in upstream and downstream equipment and controls.

Types of Parts

Barrels

Cutters

Extrusion Dies

Mixers and Feeders

Screws

System Controls

Twin-Feed Packers

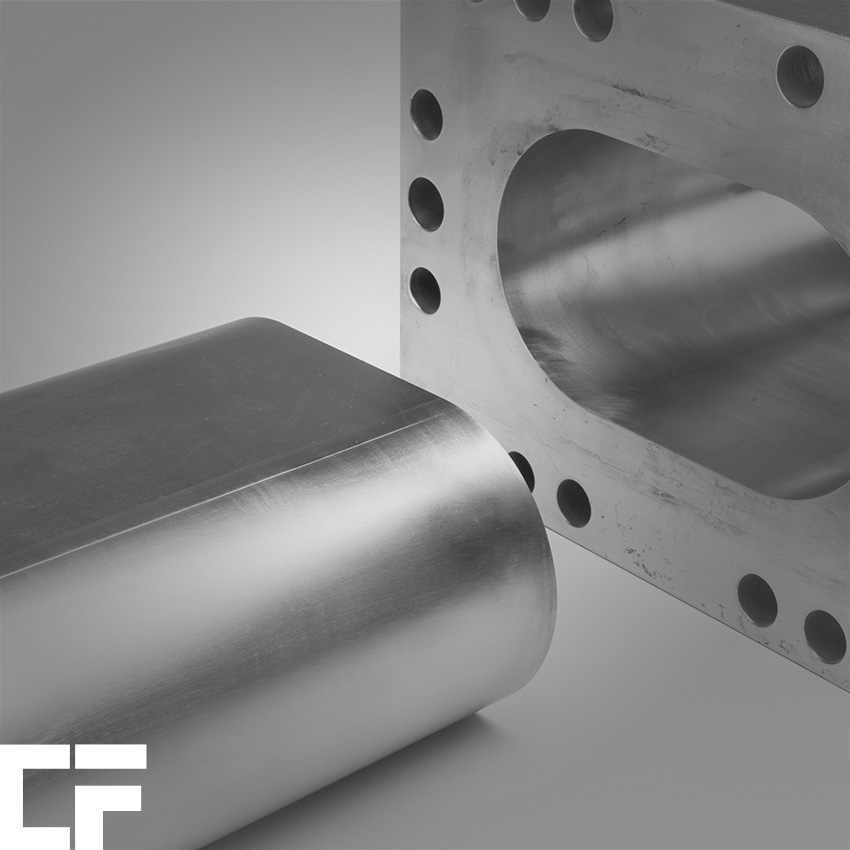

BARRELS

- From 25MM to 177MM for most brands of single-screw and twin-screw extruders

- Standard and OEM configurations

- Tungsten carbide, silicon carbide and powdered metal barrels for high abrasion and corrosion resistance

- Sleeve barrels split for ease in cleaning and maintenance

- Clam shell barrels for highly abrasive materials for quick changeout of liners

- Barrel accessories

CUTTERS

- Standard and custom guillotine cutters for a wide range of cutting requirements, designed with downstream equipment in mind and unlimited range of profiles

- Rotary cutters with multiple blade and wire cutting selections, with a number of high-speed options for use in inline and offset cutting

- Inline and offset fly-knife cutters for fast, clean, consistent cuts

EXTRUSION DIES

- Innovative profiles with detailed finishes

- Standard specialized extrusion dies

- Custom dies engineered for any application

- Profile dies, monolith dies, button dies, and more

MIXERS AND FEEDERS

- Lab size to production size

- Custom designed to specific needs

- Bulk feeder for large, difficult-to-handle materials

- Twin-shaft feeder for sticky or difficult materials

- Standard twin-shaft mixer models in 2”, 4”, 6”, and 8” barrels

- Can be fitted with shredding die assembly

- Options available for adding more shear to the process

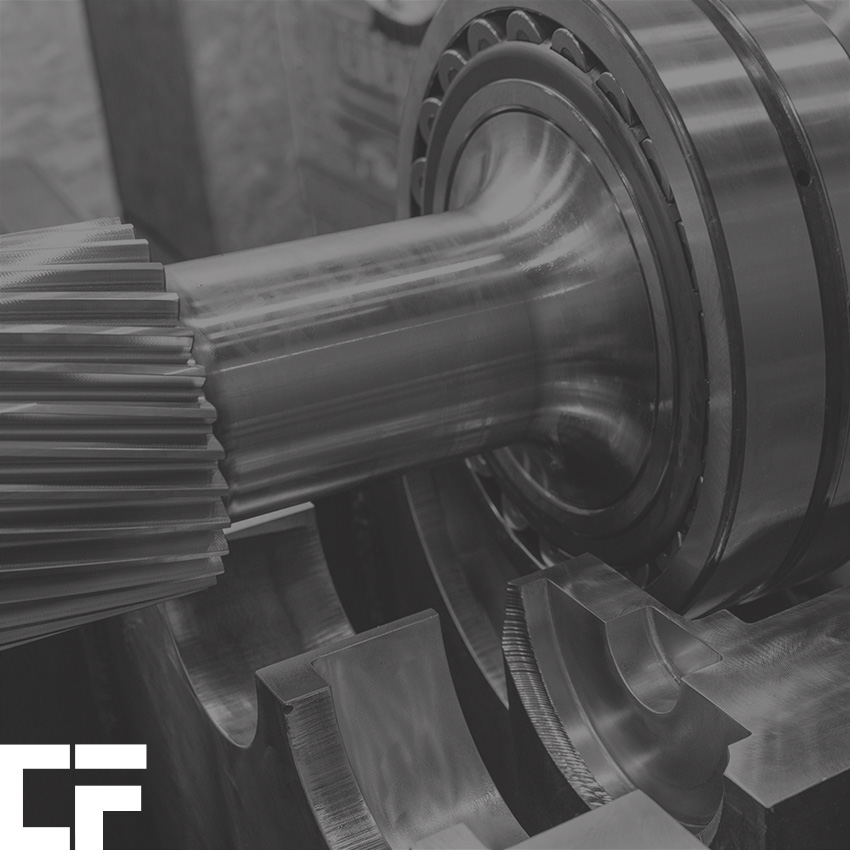

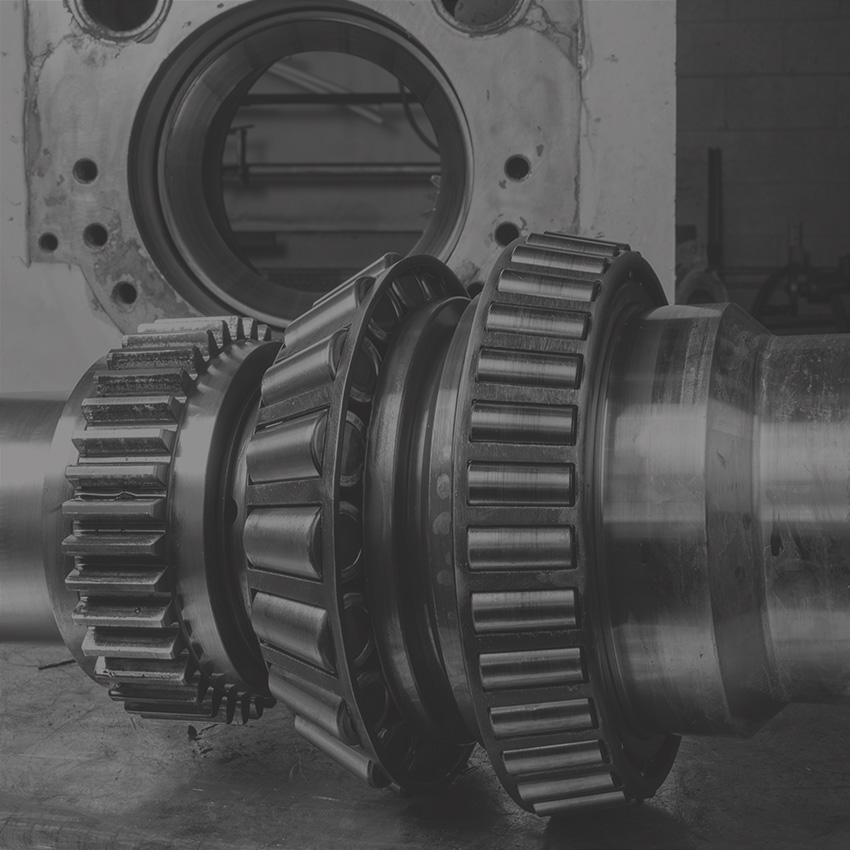

SCREWS

- Standard Extruder screws with continuous and slotted 6:1 L/D ratio

- Custom Extruder screws to meet specific processing needs

SYSTEM CONTROLS

- Equipment to monitor and control every stage of the process

- Temperature, pressure, and speed control to ensure consistency

TWIN-FEED PACKERS

- Counter-rotating feed screws and combination of feeders, extrusion screws, and barrel liners combine to digest almost any product

- Built-in self-cleaning action prevent material from becoming clogged or dormant at any stage in the system

LEARN MORE ABOUT WHAT MAKES CF EXTRUSION UNIQUE

Customized Extrusion

Our extrusion specialists will research, design, build and test a solution specific to your requirements. Our equipment is designed to meet the specific needs of each individual customer and is built to exceed the highest standards.

Outperformance Parts

We do more than simply manufacture extruders and their parts. CF Extrusion designs and builds replacement parts with high-grade materials and features that outperform the original equipment, with extremely fast lead times.

Rebuild Services

With over 90 years of collective experience, our team of engineers is uniquely qualified to tear down and rebuild your machine to like-new condition, extending the life of your extrusion unit.

CALL US @ (844) 439-8783 OR USE OUR ONLINE FORM

Mission Statement

CF Extrusion Technologies designs, engineers, and manufactures custom extrusion technology solutions.

MORE ABOUT US

Our Addresses

Shipping/Receiving

2748 2nd Street

Suite C

Cuyahoga Falls, OH 44221

Mailing Address

P.O. Box 272

Cuyahoga Falls, OH 44222

Get In Touch

Reach out to us if you have any questions. We look forward to helping you with your next project.

Email Us

info@cfextrusion.com

Additional Resources

©2022 CF Extrusion Technologies | All Rights Reserved. | Made by MONSTERS